We first heard of Milwaukee’s new hydraulic (“oil pulse”) driver, the Surge™, through an inadvertent leak from the Home Depot web site that had a page posted several weeks too early. The page included photos and specifications, but it was taken down quickly, leading to a lot of speculation and uninformed comment. Today, 10/10/2016, is the day the Surge is officially announced! I was given the opportunity to learn about the Surge™ and try one at the 2016 National Electrical Contractors’ Association convention in Boston a few days ago. I was favorably impressed before I even finished driving my first good sized fastener.

We first heard of Milwaukee’s new hydraulic (“oil pulse”) driver, the Surge™, through an inadvertent leak from the Home Depot web site that had a page posted several weeks too early. The page included photos and specifications, but it was taken down quickly, leading to a lot of speculation and uninformed comment. Today, 10/10/2016, is the day the Surge is officially announced! I was given the opportunity to learn about the Surge™ and try one at the 2016 National Electrical Contractors’ Association convention in Boston a few days ago. I was favorably impressed before I even finished driving my first good sized fastener.

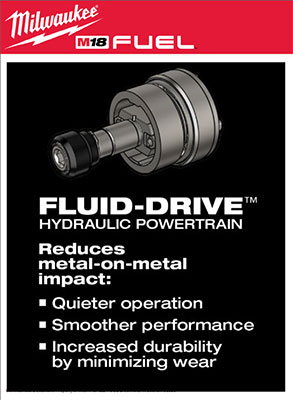

Why are we looking at another iteration of the M18 Fuel™ Impact Driver so soon after the introduction of the Gen 2 and ONE-KEY™ versions? Because the Surge™, while looking familiar, is a very different animal. It’s not a conventional impact driver, moving away from the conventional “hammer and anvil” design to employ hydraulic impulses to generate the impacts characteristic of this type of driver. The goal, and result, is a driver that Milwaukee tells us produces ⅓ the vibration of previous models and 50% less noise. When we consider that impact drivers are some of the noisiest and most prolific tools on many jobsites, this is a significant advance. It’s achieved through the use of a totally different mechanism that greatly reduces metal-to-metal contact within the tool.

Milwaukee’s Cole Conrad showed me the impulse mechanism at the NECA convention and explained how it worked. When I first saw the internals, I was immediately reminded of the Wankel engines that appeared in the rotary powered Mazdas in the 70s. The reference is not unfounded. The piece that spans the diameter of the casing in the accompanying graphic has movable “wipers” at each tip. When they reach the shoulders seen at the top and bottom of the chamber, they are forced inward, pressurizing the oil which in turn compresses a bladder in the rear of the mechanism. The energy stored so briefly in the bladder is then imparted to the driveshaft as a hydraulic impact rather than a metal-to-metal strike.

Milwaukee’s Cole Conrad showed me the impulse mechanism at the NECA convention and explained how it worked. When I first saw the internals, I was immediately reminded of the Wankel engines that appeared in the rotary powered Mazdas in the 70s. The reference is not unfounded. The piece that spans the diameter of the casing in the accompanying graphic has movable “wipers” at each tip. When they reach the shoulders seen at the top and bottom of the chamber, they are forced inward, pressurizing the oil which in turn compresses a bladder in the rear of the mechanism. The energy stored so briefly in the bladder is then imparted to the driveshaft as a hydraulic impact rather than a metal-to-metal strike.

Some of the energy imparted to the powertrain by the Fuel™ brushless motor is inevitably absorbed by the hydraulic fluid, more than is lost to friction in a hammer and anvil set-up. This leads to lower maximum torque numbers for the Surge™, creating a false impression of drastically reduced capability. My hands-on experience proves that the Surge™ equals the performance of my prior three generations of Milwaukee Impacts in all but the heaviest use. I saw no difference in performance driving 6″ Timberlock™ fasteners into 4″ x 6″ yellow pine. The specs, however, present Milwaukee with a tough sell to those who have not had the opportunity to try the tool. When current impacts boast numbers in the 1800 to 2000 in/lb., the Surge’s 450 sounds like a mistake!

The 450 in/lb. spec is no mistake, but there are factors that make that 450 in/lb. work as hard for us as the big hammer and anvil number in most applications. Milwaukee attributes the performance to longer sustained torque. I’ll offer a speculation on how that is: With a hammer and anvil mechanism, the hammer imparts high energy initially upon strike, but rebounds very rapidly, so the energy given is already “over”, in a sense, immediately after that initial strike. With the hydraulic mechanism, the pulse is not subject to the same rebound, so is able to impart the energy over a longer period of time. Add to this the increase of 1000 IPM over the hammer and anvil versions and it’s easy to understand the greater efficiency.

Okay, enough about that! The Surge™ looks very much like Milwaukee’s previous drivers, but a noticeable difference is in the nose. It’s covered by a soft, translucent, vented shroud. The Surge™ has vents for the mechanism because the rapid cycles of pressurization generate a fair amount of heat. The vents allow cooling air to be driven across the mechanism, but the mechanism is sealed, so there is no threat of dirt or debris fouling it. While the shroud is ostensibly for protecting finished work pieces, it (cough, cough) also contributes to the noise reduction.

Okay, enough about that! The Surge™ looks very much like Milwaukee’s previous drivers, but a noticeable difference is in the nose. It’s covered by a soft, translucent, vented shroud. The Surge™ has vents for the mechanism because the rapid cycles of pressurization generate a fair amount of heat. The vents allow cooling air to be driven across the mechanism, but the mechanism is sealed, so there is no threat of dirt or debris fouling it. While the shroud is ostensibly for protecting finished work pieces, it (cough, cough) also contributes to the noise reduction.

Why and Where

If you already have an impact driver the sinks every fastener you use, why might you want Milwaukee’s Surge™ when it’s not optimal for large diameter fasteners? The answer lies in its smoothness, small size, light weight and reduced noise. Although the hydraulic mechanism is not a radical departure from others on the market, Milwaukee attributes the Surge’s ™ good performance to their combining it with the POWERSTATE™ Brushless motor, the REDLINK PLUS™ intelligence built into the tool and their REDLITHIUM™ battery packs. Spending a day with a hammer and anvil impact driver, or several of them, is no picnic. Nor is a heavier, larger hydraulic driver. The Surge™ will perform as well or better than conventional impacts doing perhaps 90% of the work we do without taxing us the way larger, heavier louder tools do. I consider noise reduction to be the most important advance in impact driving. Days, weeks and years working in high noise environments take a toll on our hearing. With the Surge™ falling below OSHA’s mandated noise level that requires hearing protection, today’s tradespeople can take advantage of a technology that will benefit us for years to come. Now if I just didn’t spend so much time in a rock ‘n’ roll band…

-dvl

Leave A Comment