In the early 1970s, my parents bought an old Nantucket house with a kitchen in need of considerable renovation. My father paneled the walls above the counter tops with some very nice, wide 5/4″ pine boards that he hand-planed, hand-beaded and ship-lapped. The window trim was also beaded and I became so enamored of the look that I was eager to duplicate it. The problem was that I had no tools that would make that particular molding. I searched in vain through several professional tool stores in New Jersey for a router bit that could produce the desired profile, but came up empty-handed. There were some molding cutter heads available for table saws that were near to what I was looking for, but much coarser than the shapes I had in mind.

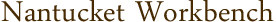

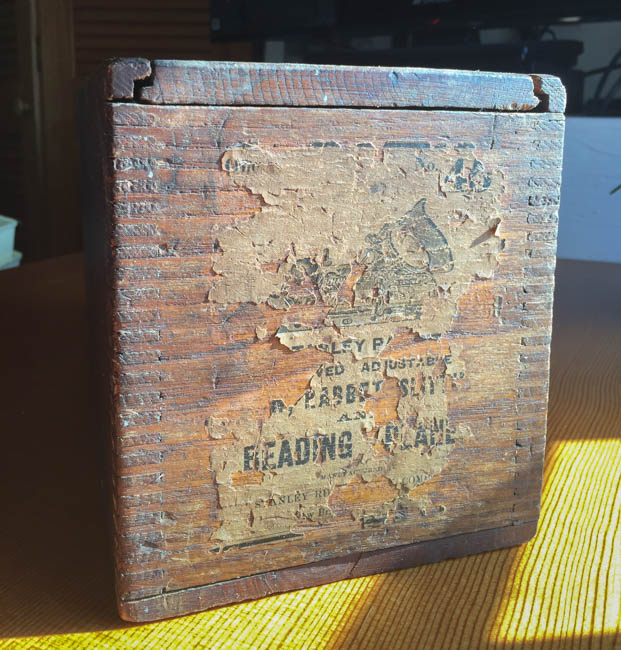

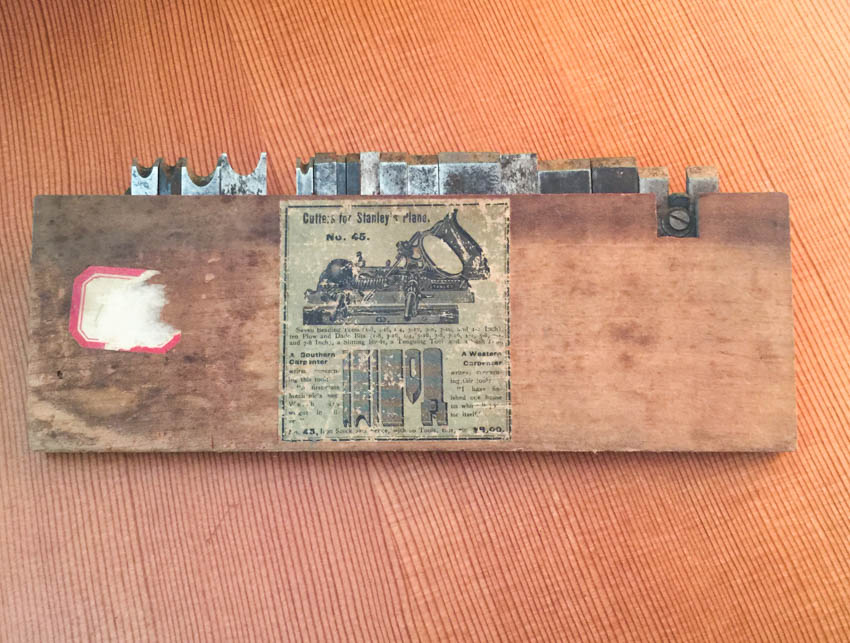

Dad beaded all of his stock with a Stanley 45 molding plane. As he lived in Massachusetts and I in New Jersey at the time, his was not available to me, so I had to look for my own. After a lot of fruitless hunting that could be attributed to having to compete with tool collectors, I finally found a nice one in a flea market in Neshanic Station, about a 200 yard walk from where I was living! Memory tells me that I paid $150 for it, and was happier than the seller when he saw how another vendor had priced his. I did a fair amount of beading with this plane until the fall of the Soviet Union.

The way I understand it, it was not practical to make cutters and bits with fine profiles until carbide cutting edges were widely available. This availability was ostensibly due to carbide no longer being considered a controlled, strategic material as the cold war ended.

This was the same time that titanium started showing up in racing bicycles, (I still wonder who pinched Ron Skarin’s Teledyne) and for the same reason. Either I’m correct in my understanding or I’m spreading an apochryphal tale, but it’s good in the telling. I now do my beading on a router table with carbide bead bits that do a clean job in a small fraction of the time.

A few years later my father John, Michael Phillips, John Holland and I put a new slate roof on the house known as East Brick on Nantucket’s Main Street. Dad already had slate tools, but I had to search for some, as they are less than a staple of the average hardware store. I was lucky to find a slate hammer and bench at the same flea market in Neshanic Station.

The pointed end is for popping holes in the slate for the copper nails that fasten each to the roof, and for perforating the slates along the intended cut line. The flat shank between head and handle has cutting edges fore and aft for cutting and trimming along the perforations made by the point. I can only guess that the striking surface is that small to discourage great whacks at the nails, and because the tool is shaped from flat stock to begin with. Tapping, rather than anything more energetic, was the order of the day, at least for me!

The slate bench is a curious tool. The way to use it is to whack the pointy end into a plank where you’re working, then lay the slate on it so the line where you want to cut it is near to and parallel to the length of the bar. After popping a series of holes along the line and snapping off the discard, the new edge can be trimmed with the cutting edge of the hammer and appropriate nail holes can be punched in while the slate is supported on the bench. Then it’s ready to go.

I have only had the opportunity to use these slate tools on two roofs, both on Main Street, but I won’t give them up even though I will do my best to leave roofing to the younger lions. The Stanley 45 is definitely retired!

Leave A Comment